Need some help?

We would love to help you with your project.

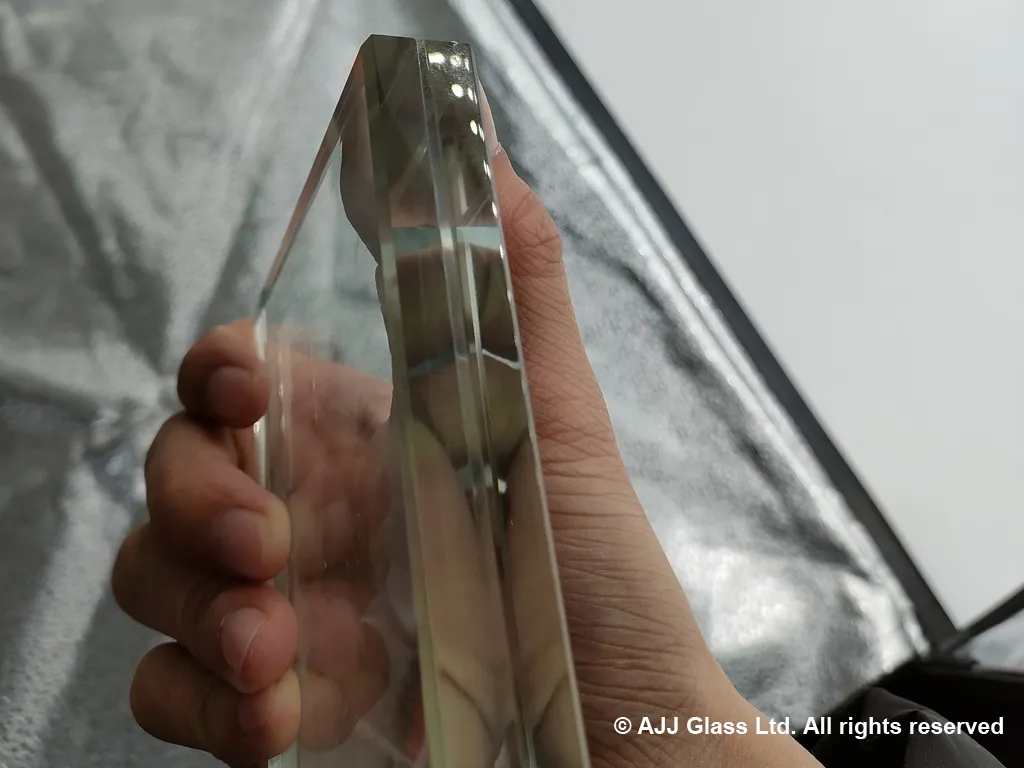

Toughened glass is a Grade ‘A’ safety glass produced by furnacing annealed float glass at an approximate temperature of 620oC. After some time in the furnace chamber, the glass moves into a quenching chamber where it is rapidly cooled by high-pressure air. This ‘snap’ cooling or quenching induces compressive stresses to the glass surface, whilst the center remains in tension resulting in a product that is 4-5 times stronger than ordinary annealed float glass.

Railings, glass doors and partitions, shower doors and enclosures.

Architectural – 4mm to 12mm Grade ‘A’ safety glass manufactured to AS/NZS 2208-1996 Safety glazing materials in buildings and 15mm to 19mm Toughened glass.

The Australian/New Zealand standard for safety glazing materials assesses the impact resistance of tempered glass. It classifies glass based on the drop height required to break it and provides guidelines for its use in different applications.

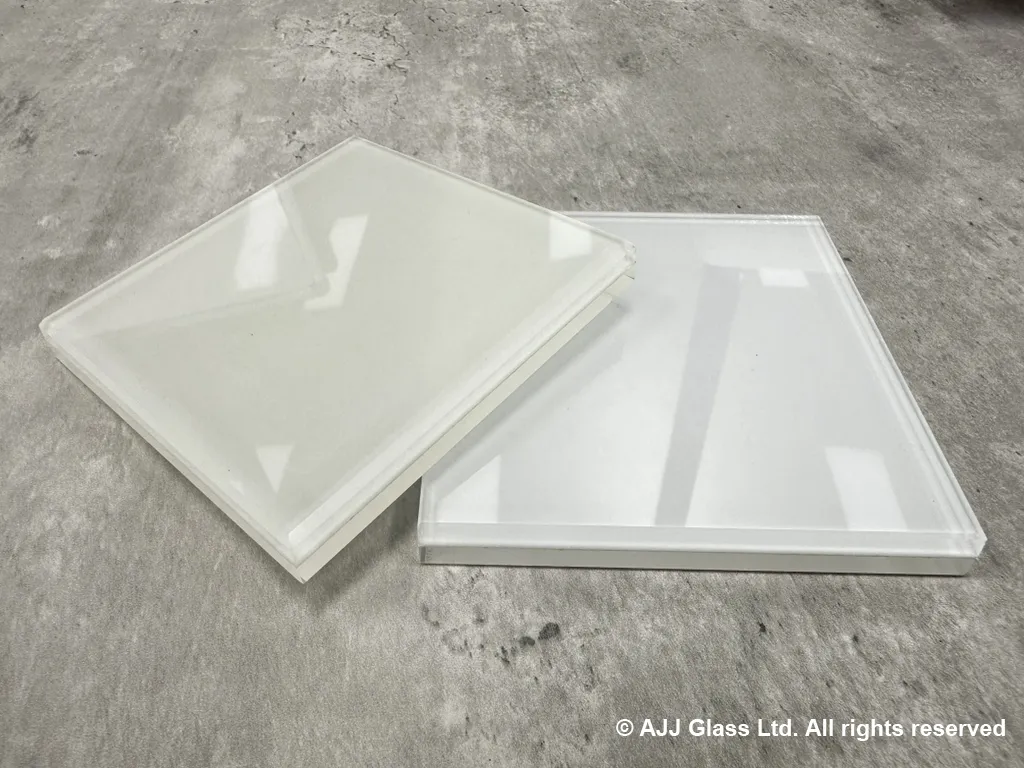

Laminated glass is a Grade ‘A’ Safety product made by laminating two or more panels of glass with a flexible plastic interlayer or PVB (polyvinyl butyral).

From metallics and pearls to custom art, the design possibilities are endless.

Glass across a full spectrum of vibrant colors, available in a range of translucency levels.

With a stylish frosted appearance, PurColor™ Translucent is durable, reliable, and designed to secure your privacy.