Need some help?

We would love to help you with your project.

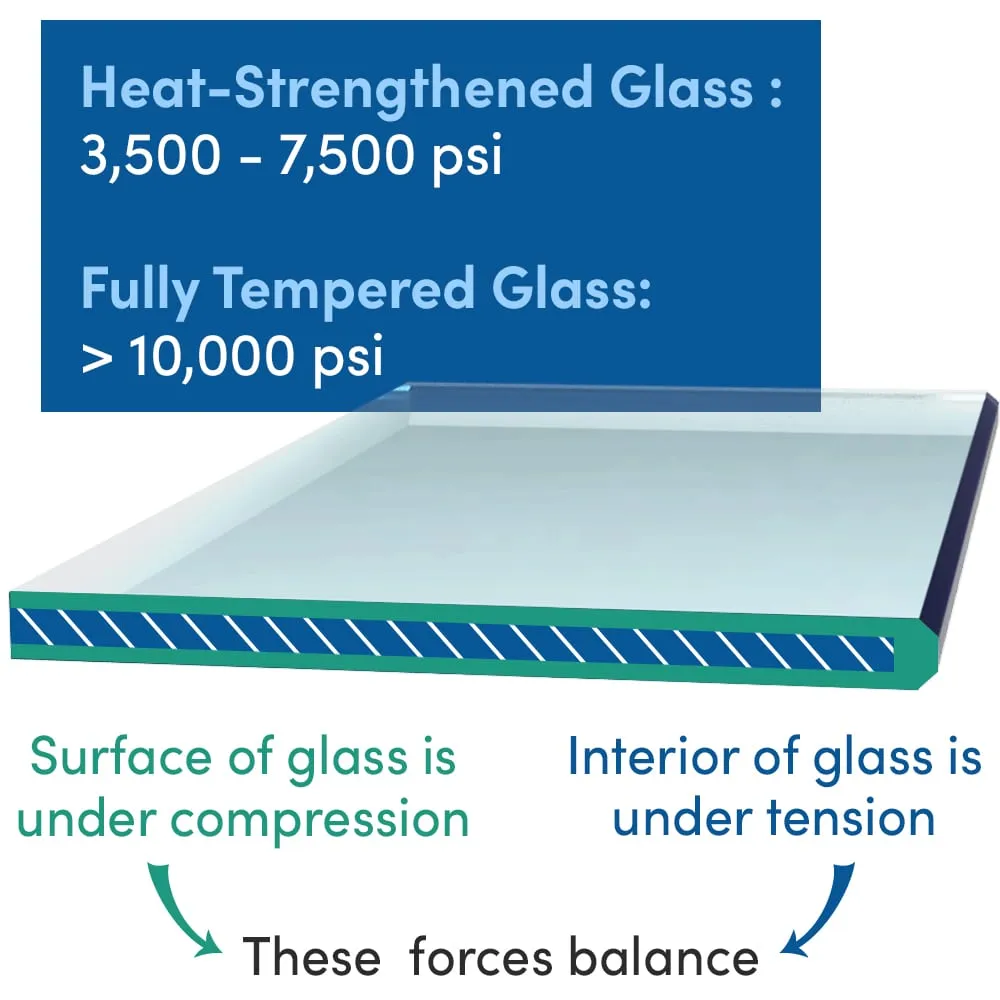

Heat-treated glass is a term used to describe the product that results from introducing Annealed architectural glass into a tempering oven at a temperature of approximately 1,150° F, and then subsequently exposing both sides of the glass to high-pressure cooling or “quenching” conditions that serve to induce permanent zones of glass surface compression. As glass undergoes this procedure, its physical properties are altered where there is a significant increase in residual surface compressive strength and overall resistance to shock and thermal stress. There are two general categories of heat-treated glass – heat-strengthened glass and fully tempered glass, both of which AJJ produces in strict accordance with the requirements and tolerances outlined in ASTM C1048. Heat-strengthened glass is twice as strong as annealed glass. It is better suited to resisting thermal stresses and edge damage and features a breakage pattern that is more likely to be retained within a glazing frame in case that breakage occurs. Fully tempered glass is four times as strong as annealed glass. It too offers superior resistance against thermal stresses and edge damage, but its breakage pattern is more conducive to having glass fall out of a frame when breakage takes place. Because of that and how fully tempered glass breaks into small, relatively harmless pieces, it is classified by building codes as a suitable option where “Safety Glass” is required.